DICY (Dicyandiamide)

| Description | |||

| DICY is one of the major curing agents in Epoxy powder coating, white powder with density of 1.40/cm3, melting range at 207~209C, which is stable when in dry powder. | |||

| Specifications | |||

| Item | X -Grade | S-Grade | G-Grade |

| Appearance | White crystal | White Crystal | White Crystal |

| Impurity precipitating test | Approved | Approved | Approved |

| Purity % min | 99.5 | 99.0 | 98.5 |

| Dry Loss % max | 0.30 | 0.50 | 0.60 |

| Ash content % max | 0.05 | 0.10 | 0.15 |

| Calcium Content, ppm, max | 200 | 400 | 500 |

| Applications and packing | |||

| a. Mainly used in powder coatings and CCL.

b. 25kg/PPbag with PE liner, store in cool, dry and ventilated place. |

|||

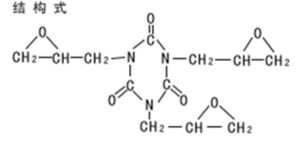

TGIC: Tris(2,3-Epoxy propyl Isocyanurate)

| Introduction | ||

| TGIC is an isocyanurate base crystalline polyepoxide compound, as the curing agent for polyester type and acrylic stype powder coating system, with the properties of good heat and weather resistance along with excellent high temperature stability.

|

||

| Specifications | ||

| Item | TGIC105 | TGIC110 |

| Appearance | White powder or granule | |

| EEW | 105 min | 110 min |

| Chlorine content | 0.4% max | 1.5% max |

| Melting range | 90-125C | 90-125C |

| Melt Viscosity(125C) | 100 cps max | 100 cps max |

| Volatile | 1% max | 1% max |

| Free ECH content | 50 ppm max | 50 ppm max. |

| Particle size | 3-12 mesh | 3-12 mesh |

| Packing and storage | ||

| a. 25kg/fiber drum with PE liner

b. Store in dry and venting, clean indoor, keep away from moisture, heat and flame. |

||

Accelerator and Hardener CA-31 (4, 5-di hydro-2-phenyl-1H-imidazole)

| Description | |||

| CA-31is a curing accelerator for epoxy resin. With the chemicals structure containing cyclic amidine with good compatibility with the base resin alone and with less yellowing property when compare with 2-methyl imidazole after baked, which are mainly used for the coating of automobile spring and shell capacitor. | |||

| Specifications | |||

| Appearance | Light yellow crystal or flake | ||

| Melting range | 95-101 C | ||

| Recommended formulation | |||

| Item | Epoxy resin (EEW 850-1000) | Epoxy Resin (EEW750-850) | |

| Epoxy Resins | 56.0 | 55.5 | |

| CA-31 | 3.5 | 4.0 | |

| TiO2 | 40 | 40 | |

| Leveling agent | 0.5 | 0.5 | |

| Packing and storage | |||

| a. 20kg/paper bag with PE liner

b. Store in dry, dark and ambient place. c. Prevent from pre-crosslinking please keep the extrude temp. below 100C |

|||

HAA PE-552 (β – hydroxyalkylamide – Primid curing agent)

| Introduction | |

| PE-552 is a curing agent suitable for the production of outdoor polyester powder coating system, It has the characteristics of low toxic, no irritation to skin, good weather stability, widely used as the substitute for TGIC.(available from Jan.01, 2008) | |

| Properties: | |

| Appearance | White powder |

| Melting range | 124-129C |

| OH value g/eq. | 82±2 |

| Non Volatile: % min. | 99 |

| Recommended formulation | |

| CC7630(UCB) (Acid value:35mgKOH/g) | 62.5 |

| PE-552 | 3.3 |

| Leveling agent (polyacrylate with silica as carrier) | 0.8 |

| Benzoin | 0.5 |

| TiO2 | 32.9 |

| Packing and storage | |

| a. 25kg/paper bag with PE liner.

b. Keep in dry place prevent from moisture and flame. |

|

HAA PE-552LY ( Primid curing agent – less Yellowing than 552)

| Description | |

| PE-552LY also contain β-hydroxy alkylamide but further blend with degassing agent to increase its non yellowing properties alone with better flow when compare with PE-552, it will decrease the dosage of benzoin which is the major cause of yellowing when baked. | |

| Specifications | |

| Appearance | White powder |

| Melting range | 130-145 C |

| OH Value: g/eq. | 100±2 |

| Non Volatile, % min. | 99 |

| Recommend formulation | |

| Polyester CC7630(UCB)

(acid value:30-35 mgKOH/g) |

61.7 wt% |

| PE-552LY | 4.3 wt% |

| Leveling agent

(polyacrylate with silica carrier 70% active content) |

1 wt% |

| Pigment | 33 wt% |

| Note: extrude temp. 110~120C; baking condition: 180C/15 min.; film thickness: 50-100um | |

| Packing and storage | |

| a. 25kg/paper bag with PE liner

b. Keep in dry, dark and prevent form heat, moisture and flame. |

|

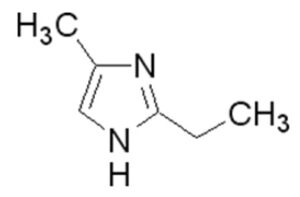

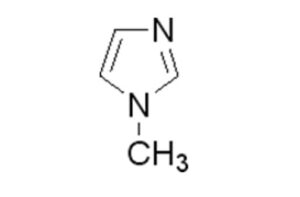

IMIDAZOLE (accelerators and curing agents)

| Description | ||

| Imidazole is perform as the accelerator for Epoxy widely applied in powder coating, binder, sealant and composite materials. | ||

| Properties | ||

| Item | 2-E-4-M-1H-Imidazole | N-Methyl imidazole |

| Chemicals | C6H10N2 | C4H6N2 |

| Molecular weight | 110.16 | 82.10 |

| Molecular Structure |  |

|

| Appearance | Yellowish transparent liquid | Colorless and transparent liquid |

| Density | 0.975g/ml at 25C | 1.031g/ml at 25C |

| Freezing pint | – | -60C |

| Boiling point | 292-295C | 198C |

| Flash Point | 137C | 92C |

| Melting point | 47-54C | – |

| Assay | 96% min | 99% min |

| Water Content | 0.2% max | 0.5% |

| Application | Accelerator for Epoxy | Materials for accelerator and

Organic synthetic materials |

| Packing | 20kg/fiber drum | 200kg/drum |

| Storage | Keep in dry and dark place keep away from moisture and heat | |